Industrial vibrators are designed to facilitate the flow of wet or dry materials in bins, hoppers, chutes and pipes, railcars, bulk trailers, and trucks. The right vibrator can energize and maintain the movement of material by reducing both the coefficient of friction between the bulk material and the structure's walls and the bulk material's particle-to-particle cohesion and interlocking. The wrong vibrator can compound the handling problem by compacting the material, damaging the structure being vibrated, wasting energy, and creating unwanted noise.

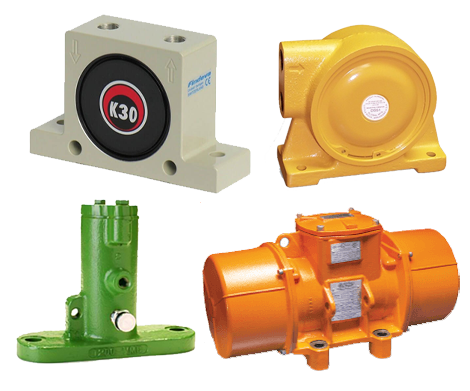

For more than 75 years, we at AIRMATIC have been at the forefront of solving bulk material flow problems, successfully prescribing countless vibrators to improve the flow of powders and bulk solids into or out of material containments. We have used rotary air vibrators, rotary electric vibrators, electromagnetic vibrators, and piston air vibrators to solve problems in a range of applications in industries that include feed and grain, mining, pharmaceuticals, concrete construction, aggregate, manufacturing, cement, food, plastics, power generation, water filtration, waste handling, and public utilities. Vibrators are economical to buy, install, and operate, and can be retrofitted to existing structures. When properly selected and controlled, they will allow speed and force adjustment should the operating requirements or bulk material change.

We offer the most extensive range of air and electric vibrators in the material handling industry. Talk with us about what solutions would best suit your needs.